The electronic on-board system is able to manage the different regenerations by regulating the difference in pressure (electronic differential pressure switch) and temperature (K-type probes).

In spite of that, an inappropriate use of the engine can clog the filter quite rapidly. If a diesel car is mainly used on urban routes, there will be an excessive production of particulate, but very few occasions to burn it, as the gas will not reach high enough temperatures. In such an operating condition, a FAP or a DPF can clog after only 5-10,000 Km.

If, on the other hand, the car is mainly used on motorways, with high operating temperatures and more chances to have a stoichiometric combustion, the amount of particulate will be much lower, and regenerations more frequent. In that case, the clogging of the filter may happen after 150-200,000 Km, if at all.

In any case, whenever the filter is clogged, it has to be replaced.

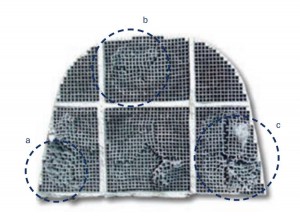

A, b and c indicate areas where the filter has partially melted down. Channels are distorted and deformed because of the accumulated heat and the stagnation of residual dusts. The FAP was cleaned, but that didn’t remove the particulate, which is chemically bound to the filter.

Washing the filter is useless, because water and other cleaning liquids will not affect the clogged pores of the substrate.

In some cases, the excessive obstruction leads to a local accumulation of heat in some areas, caused by non-expelled gas.

These areas can melt down, damaging the structure of the filter and posing the risk of further damages to the whole engine, such as overheating of the valves, breakage of the catalytic converter and clogging of the conduits.

The solution to this problem is the total replacement of the filter with a new one. To make it last longer, the new filter has to be impregnated with platinum and palladium.

The conventional regenerated FAP provided by carmakers is completely new, but it comes at a discounted price because the ceramic and metal parts of the old filter can be recycled and used for different purposes.